But the Austrian, Paul Pretsch took a completely different approach and patented a process called 'photo-galvanography'' in 1854 [15]. He discovered, while he was manager of the Imperial Government Printing Office in Vienna, that gum arabic sensitized with potassium dichromate, silver nitrate and potassium iodide on a glass plate, sensitized under a photographic negative to sunlight, had a tendency to swell and reticulate when washed in water. The depth and intensity of the worm-like texture that was produced was proportional to the exposure and gave the ‘grain’ required for half-tones. He then created a mould of the reticulated gelatine with gutta percha, which was a widely used gum from a Malayan tree. He then deposited copper by galvanoplasty onto the mould, which duplicated the original reticulated gelatine. To print it in intaglio, he had to make a second electrotype of his matrix. He filed another patent in 1855 describing refinements to his process, using gelatine instead of gum, hardening it with tannin and applying the process to making relief prints. He formed a company in London to produce a series of albums of commercially printed photographs called "Photographic Art Treasures" in 1856 and employed Roger Fenton as his photographer and manager [14].

Paul Pretsch - 'Photographic Art Treasures' - Title page 1856 |

Sadly his venture was not a commercial success - the process of production of each plate took about six weeks, and he was dogged by lawsuits from Fox Talbot who claimed that his Photoglyphic patents covered Pretsch’s inventions. In the end he proved the originality of his work but the company folded in 1858. He was awarded medals for his half-tone photo-galvanographic plates at the Great Exhibition of 1862, and was a finalist in the Duc de Luynes competition 1867. He did a great deal of work illustrating the Journal of the British Museum, but found it difficult to get on in London, and returned to Vienna a disappointed man, and died of cholera in 1873.

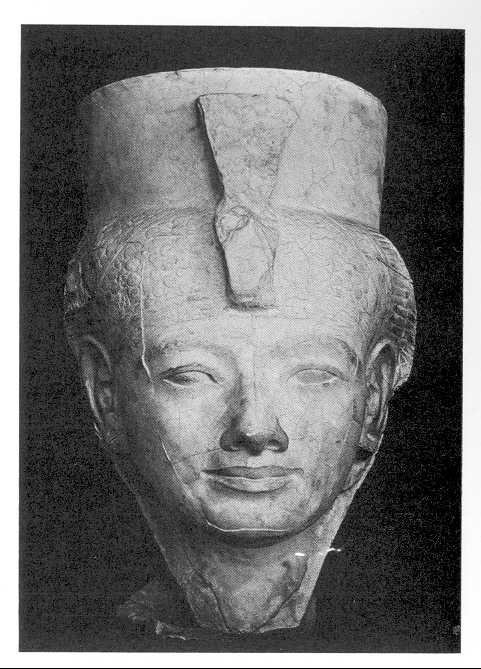

Pretsch - illustration in Photographic Art Treasures |

Alphonse Poitevin, aware of the pioneering work of Pretsch on the reticulation of gelatine, filed a number of patents in 1855 for a very similar process, substituting a plaster of Paris mould for the gutta percha. But he turned his attention to the behaviour of dichromated albumen exposed to light on a lithographic stone, and it is with this method that he won the prize for photomechanical printing offered by the Duc de Luynes in 1867. He is also credited with being the originator of the technique of collotype, which uses the carefully controlled reticulation of exposed and heated gelatine on a glass plate, which is then printed like a lithograph. Collotypes were capable of reproducing photographs with exceptional detail and subtle silky half-tones, and the technique was perfected by Otto Albert in Berlin in the 1870's [4].

Ricci/Otto - Collotype 1890's |

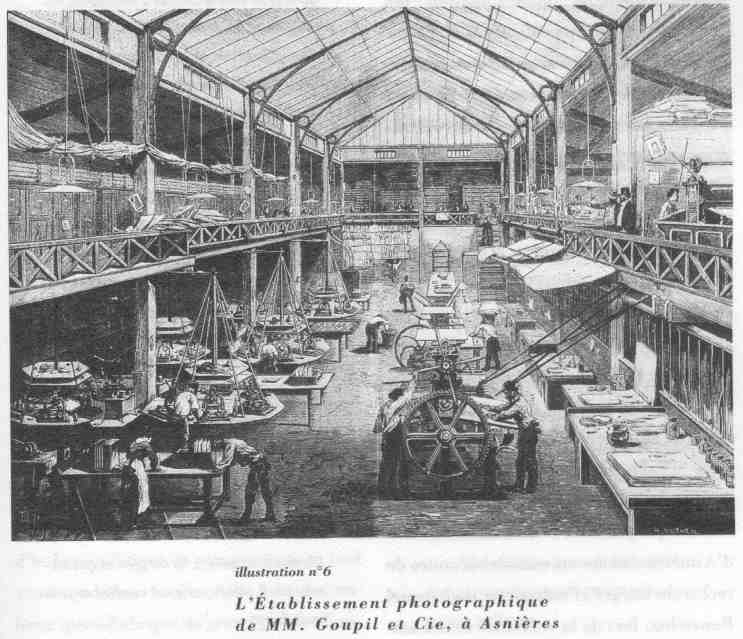

Although it was not an electrolytic technique, the method patented by Walter B Woodbury in 1866 is of very great interest here, because it was licensed for use in France by the firm of Goupil & Cie, publishers of Fine Art reproductions. They set up a factory at Asnières to produce "photographie photoglyptique" or "Woodburytypes". It was not strictly a printing process, but a method of reproducing the three-dimensional image of a gelatine print in which the depth of tone was given by the thickness of coloured gelatine. The original produced by a purely photographic process on a metal plate, was cold pressed into a lead mould, which was then used to impress hot coloured gelatine onto paper [3].

Goupil & cie - Woodburytype factory |

The reason Goupil's use of this process is interesting here is because they later started producing reproductions of photographs by a different process from copper plates, but kept the precise process a closely guarded secret [6]. The results were exceptionally good, with rich velvety blacks and subtle half tones, although a lot of hand work is evident on the plates, a process which earned the name of "Goupillage". The author of this article has examined some of their plates, conserved in the Musée Goupil in Bordeaux, and believes that they were produced by an electrolytic process related to Paul Pretsch's photo-galvanography in which they used the Woodburytype press to make a lead mould of a reticulated or grained gelatine original, on which an electrotype could be easily deposited and separated [20] .

Goupil & Cie - catalogue 1878 |

As early as 1840 Thomas Spencer described a method which was later used extensively for making large copper plates for printing Ordnance Survey maps. Lines were drawn through a thick ground with a special tool, and then copper was deposited slowly into the cleaned lines, producing a linear relief plate [9]. This method was widely used for other printing purposes besides maps, including the illustrations of Spencer's original description. Electro-etching, introduced and recommended for use in the arts, gradually became much more widely used in industry for decorating and making metal objects. The steel industry in particular took it up for applying trade marks to cast and wrought iron pieces, and until recently, when laser methods emerged, was the standard method of marking stainless steel cutlery [17].

In the 1962 S W Hayter described the electrolytic process of depositing metal into lines drawn through a ground on a metal plate that he had developed and used at Atelier17 in Paris before the war [22]. In industry electrolytic processes were used very widely, mainly for plating and protecting metal. Anodising was developed as a process for protecting aluminium. In 1943 a US company called Lectroetch adapted the Electro-Etching process to marking metals of all kinds, and is still supplying equipment and materials for the purpose. Many other companies have started to provide the same service, and electro-etching became well enough known for artists who were interested to learn about it.

Commercial Electrotyping workshop |

In Canada Nik Semenoff and Christine Christos carried out research into electro-etching in 1989, and published a paper in Leonardo, an art journal in 1991, detailing the method for artists, the equipment required, its advantages regarding safety. [23]. In Sweden Ole Larsen developed electrolytic processes, and one that he called "Polytype" was in essence the same as the "Electro-Tint" process described by Charles V. Walker in his 1855 book [24]. In the USA Marion and Omri Behr learned about the electro-etching process originally patented in 1840 by Thomas Spencer, and they received a US patent in 1992 for their improved equipment, and registered the names 'ElectroEtch', and 'MicroTint' [25]. The basic process itself has been shown to be in the public domain, as all the references to it, and its use by artists since 1840 have shown [23, 26, 27].

There has also been a revival of the original 19th century Heliography and photogravure processes using gelatine or albumen and potassium dichromate, and the best known publicist of these processes invented by Fox Talbot, is Keith Howard [29]. He has also adapted methods used in the electronics industry for etching circuit boards using thin photosensitive film applied to metal plates, and refined them for use by printmakers as a safer alternative to the photosensitive chemicals previously available.

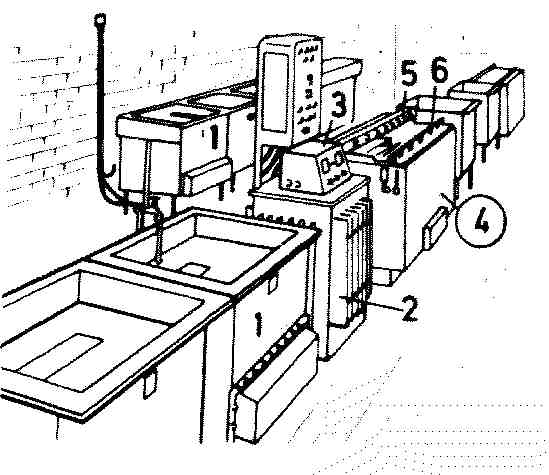

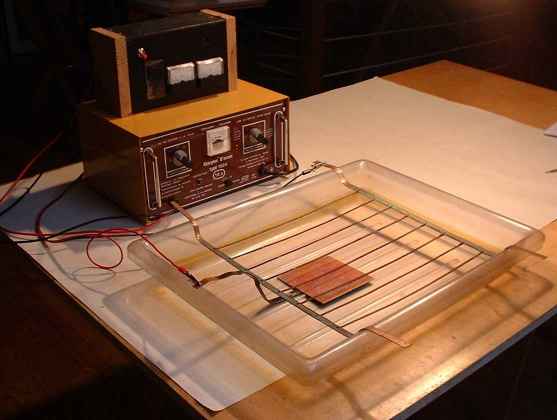

diagram of equipment for Galv Etch - Cedric Green |

I began research in 1989 into non-toxic printmaking methods for my own use, and from my base in Sheffield [UK], a traditional centre for electrolytic plating and industrial marking, I became aware of the long history of electro-etching. For my own use I found simple, safe and low cost methods for using off-the-shelf equipment for the revived electrolytic methods. I developed an electrochemical method for etching zinc and steel plates using copper sulphate which I called "Bordeaux Etch", and non-toxic methods for applying resists to plates and graining them using oil based lithographic ink which I called "Fractint" [26,27]. In 1995 I began a campaign to publicise methods in the public domain like Electro Etching, and to resist efforts to make printmakers pay royalties for using them. I created a website fully describing my low cost methods for etching electrolytically which I called "Galv-Etch", and supplied free information on all my methods (www.greenart.info).

In 1998 Nik Semenoff and L W Bader published a paper in Leonardo on an improved mordant for etching aluminium and zinc which was similar to "Bordeaux Etch" [28] .

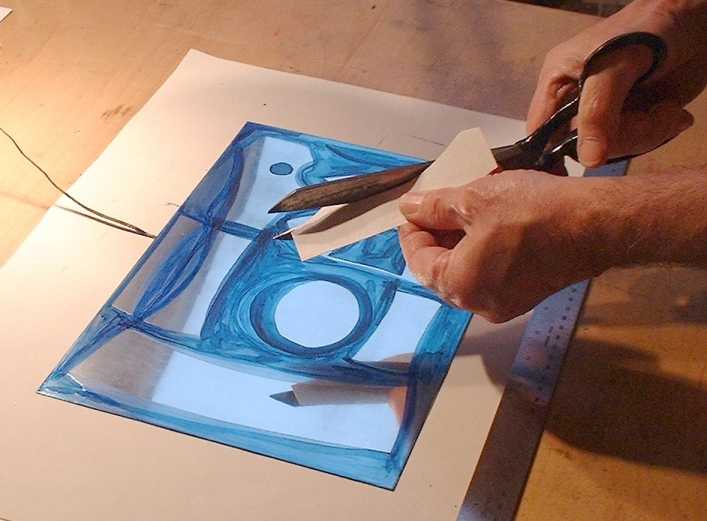

Galv-On method - preparing a plate with collaged paper resists - Cedric Green |

The subsequent development of both electrolytic and photographic plate making processes has been very rapid and has been given a great deal of stimulus by the search for so called "non-toxic" methods, or methods which greatly reduce the dangers to health and the environment that were notorious features of traditional processes using acids, solvents, and photosensitive chemicals.

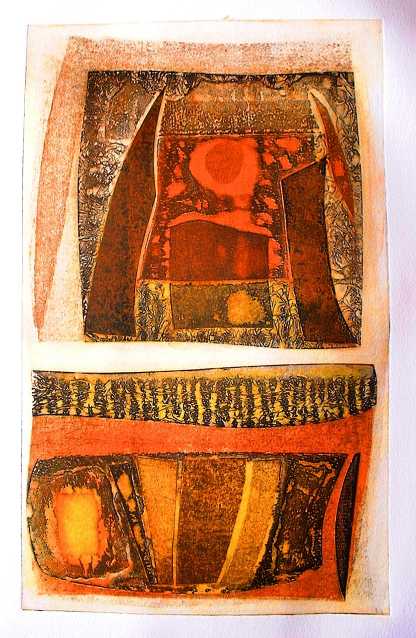

Cedric Green "Forgeron" example of Galv On technique |

References:

1 Encyclopédie Hachette Multimedia, Livres Hachette, Paris, 1999;

2 Aaron Scharf, Art and Photography, Penguin Books, London, 1968, 1974

3. Pierre-Lin Renié, "Le temps ciselé", in État des Lieux, Musée Goupil, Bordeaux, 1994.

4 Raymond Lecuyer, Histoire de la Photographie, Paris, 1945

5 Francis Haskell, The Painful Birth of the Art Book, Thames and Hudson, London, 1987.

6. William Crawford, The Keepers of Light - A History and working guide to early photographic processes, Morgan & Morgan, New York 1979

7 Encyclopoedie Larousse Illustre, Paris, 1999.

8 G. Barclay, "The First Steps in Electrotype" 2nd. edition, G. Barclay, Soho, London, 1841.

9 British Patent No. 8656 ... AD 1840, "Engraving Metals by means of Voltaic Electricity" granted to Thomas Spencer and John Wilson.

10 Mr Thomas Spencer, "An account of some experiments made for the purpose of ascertaining how far Voltaic Electricity may be usefully applied to the purpose of working in metal", Annals of Electricity, Magnetism and Chemistry, Vol.4 Jan 1840.

(See also by the same author in Westminster Review, Vol 34, II, 1840 pp 434 - 460)

11 Charles V WALKER, Electrotype Manipulation, Part II. Containing The Theory, and Plain Instructions in the Arts of Electro-Plating, Electro-Gilding, and Electro-Etching; with an account of the Mode of Depositing Metallic Oxides, and of the Several Applications of Electrotype in the Arts. Nineteenth Edition, George Knight and Sons, London, 1855.

Charles Vincent Walker, Electrotype Manipulation, Vols 1 & 2, H.C.Baird, Philadelphia, 1852.

12 Chattock R S, Practical Notes on Etching, 3rd Edition, Sampson Low, Marston, Searle, & Rivington, London 1886. (Electro-Etching for artists is described in full)

13 Hippolyte Louis Fizeau, British patent No. 9957, 1843.

14 John Hannavy, Roger Fenton, David Godine, Boston, 1976. (The process of photo-galvanography is described in detail)

15 Paul Pretsch, "Improvements in producing copper and other plates for printing", British Patent No.2373, 1854.

16 Seymour Hayden, Etching for Copper Plate Printing, The Printing Times and Lithographer, Vol 8 (1882) Oct 15 pp.247 - 248. (Electro-etching and galvanography are covered briefly)

17 Electrolytic marking is done in Sheffield by: John H. Elliot (Monostamp) Ltd. and Eyre & Baxter (Stampcraft) Ltd.; In the USA by The LectroEtch Company, who have been doing it since 1947, (email sales@lectroetch.com).

18 Charles V Walker "Electrotype Manipulation, Part I. being the Theory, and Plain Instructions in the Art of Working in Metals, by Precipitating them from their Solutions, through the Agency of Galvanic or Voltaic Electricity" 29th Edition, George Knight and Sons, London. 1859.

19 Maj.Gen. J Waterhouse, "Paul Pretsch and photo-galvanography, Penrose Pictorial Annual 1910-11 Vol 16, Lund Humphries & Co, London. (see also Maj.Gen. J Waterhouse "Mordants for Zinc" The Photographic News, June 30 1882 for a description of "etching zinc by galvanism" )

20 Otto Lilien, History of Industrial Gravure Printing up to 1920, Lund Humphries, London 1972.

21 Pierre-Lin Renié, "Goupil & Cie à l'ère industrielle - la photographie appliquée à la reproduction des oeuvres d'art", in état des Lieux, Musée Goupil, Bordeaux, 1994.

22 S W Hayter, About Prints, Oxford University Press 1962.

23 N.Semenoff and C.Christos "Using Dry Copier Toners in Intaglio and Electro-Etching of Metal Plates," Leonardo, Vol 24, No. 4, pp. 389-394, (published1991, received 1989).

24 Peter Jones, "Spanish Printmaking Summer School", Printmaking Today, Vol 2, No 3 Autumn 1993).

25 Marion Behr, "ElectroEtch I", "ElectroEtch II", "ElectroEtch III" Printmaking Today, Vol. 3, No 1, 1994, Vol 4, No.4, 1995, Vol 7, No.4 1998

26 Cedric Green, "Intaglio without Tears" Printmaking Today, Vol 7 No.1, Spring, 1998.

and "Galvanography Revisited", Printmaking Today, Vol 8 No.1, Spring, 1999. "Galv-etching without Electricity" Printmaking Today, Vol 11 No.2, Summer, 2002.

27 Cedric Green, Green Prints, Ecotech Design, Sheffield, 2002

28 Nik Semenoff and L W Bader "Intaglio Etching of Aluminium and Zinc Using an Improved Mordant" , Leonardo, Vol 31, No 2, pp. 133 - 138, 1998.

29 Keith Howard, Non Toxic Intaglio Printmaking, Printmaking Resources, 1998,

This paper was given at the 'Jornadas de Grabado no tóxico' organised by the University of Barcelona, and the illustrated Spanish version of it is available on this website. It forms part of the book in Spanish in which most of the content of Green Prints has been translated into Spanish and published by the University of Barcelona. Click here for details of this book "El Grabado no tóxico", which includes chapters by Eva Figueras Ferrer, Friedhardt Kiekeben, Keith Howard, Juan Carlos Ramos, and Rosa Vives.,